ADVANCED LIQUID COOLING FOR NEXT GENERATION INFRASTRUCTURE

Engineering & DESIGN

liquid cooling for

data centersai clusterscrypto mining

At NXC, we design and deliver advanced liquid cooling systems for high-performance data centers, AI clusters, and crypto mining operations.

Our expertise spans Direct Liquid Cooling (DLC), Hydro Cooling, and Immersion Cooling — engineered to meet the highest standards of efficiency, scalability, and reliability.

We handle every stage of the process — from concept and simulation to on-site commissioning and long-term optimization.

Each system is tailored to real operational demands, ensuring stable performance under extreme conditions, from -25°C to +46°C, and across diverse climates and deployment types.

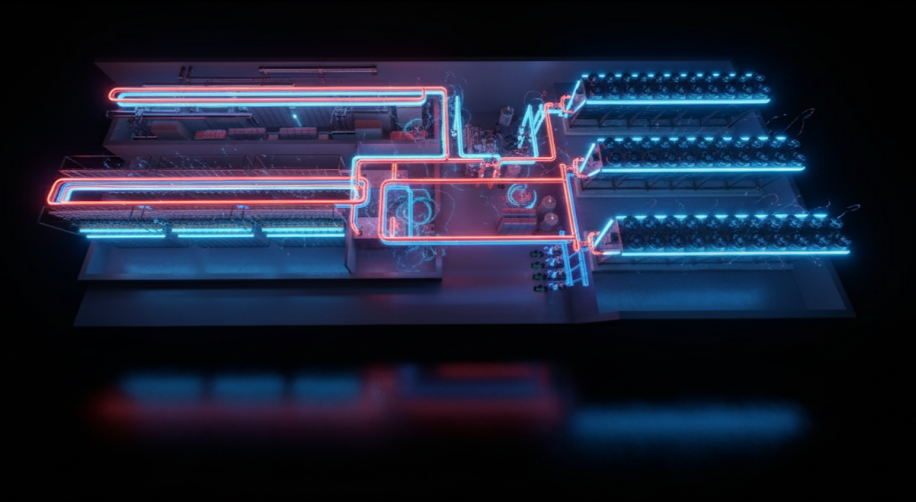

Hydro cooling and direct-to-chip (DLC)

Designed for precision thermal management in data centers and HPC environments. Our DLC and hydro systems deliver controlled temperature regulation at chip level, reducing energy use while maintaining consistent performance and uptime.

Immersion Cooling

Engineered for high-density crypto mining, AI clusters, and HPC workloads, where maximum thermal transfer, operational simplicity, and scalability are essential. Our immersion systems ensure uniform heat distribution, safe operation under sustained loads, and exceptional energy efficiency.

Custom layout and hydraulic modeling

We provide full engineering design of Technology Cooling Systems (TCS), Facility Water Systems (FWS), and Chilled Water Systems (CWS).

Our work includes hydraulic calculations, flow simulations, and component selection — from pumps and heat exchangers to valves, sensors, and automation systems.

By combining precision modeling with intelligent control logic, we ensure efficient heat rejection, balanced flow distribution, and long-term thermal stability across the entire installation.

Feasibility & Thermal Analysis

Every project begins with a comprehensive feasibility study and thermal modeling. This approach enables us to deliver optimized, field-proven systems tailored to each site’s operational and environmental conditions — from concept to commissioning. Our analyses also take into account Tier III and Tier IV data center requirements, ensuring that redundancy, reliability, and maintainability are built into the system architecture from the very beginning.

Scalable Design

Scalability is a core principle of every NXC system — ensuring your infrastructure grows as your needs evolve.

Our designs combine modular hydraulic networks, adaptive cooling loops, and flexible power architecture, allowing seamless expansion without downtime or redesign.

Each system is engineered with capacity zoning, redundancy planning, and automation layers that simplify future integration of additional racks, cooling modules, or CDUs.

Construction supervision

We work directly with on-site teams to ensure every installation meets its thermal, hydraulic, and structural specifications. Our engineers oversee mechanical assembly, piping configuration, and system integration, guaranteeing full alignment with project documentation and Tier compliance standards. This hands-on approach ensures precision execution and flawless system startup.

Commissioning and intelligent system calibration

We handle the full commissioning and automation setup process — including flow balancing, fluid validation, temperature tuning, and PLC programming. From Day One, your system doesn’t just operate — it responds. Our approach integrates real-time automation logic, sensor-based monitoring, and predictive control algorithms, enabling proactive decision-making and maximizing uptime under varying workloads.

Post-installation audits and thermal benchmarking

Following installation, we perform detailed performance validation to ensure the cooling system operates according to design intent, efficiency targets, and applicable international standards. By analyzing thermal behavior, flow balance, and energy performance, we fine-tune system parameters to achieve optimal heat rejection, stability, and long-term efficiency.

Implementation & Supervision

On-site Execution,

System Intelligence,

Performance Validation

At NXC, we don’t just design cooling systems — we bring them to life on-site.

Our team provides technical supervision, commissioning, and intelligent calibration to ensure every system meets its thermal, hydraulic, and control objectives.

By combining automation, sensor-driven intelligence, and redundancy from the start, we create infrastructures that go beyond compliance — they adapt, optimize, and perform.

From 1 MW retrofits to 20+ MW data center deployments, we deliver systems that maintain stability, efficiency, and responsiveness under dynamic loads — ensuring that when conditions change, your system is already ahead of it.

Product Solutions

Integrated Cooling Hardware

We design and deliver modular, scalable, and ready-to-integrate cooling equipment for high-density computing environments. From direct-to-chip and hydro loops to complete thermal infrastructure, our systems are built for efficiency, reliability, and seamless integration with existing facility operations.

Modular Solutions – Data Center

In the era of AI, HPC, and high-density workloads, modular data center systems are increasingly the backbone of scalable infrastructure. At NXC, we adopt a factory-fabricated, vendor-neutral, turnkey modular approach, enabling rapid deployment, reduced site risk, and future expandability. Prefabricated modules integrating power, cooling, structural, and control systems — ready for plug-and-play deployment. Design for liquid cooling (DLC / immersion) from the ground up, ensuring that cooling constraints are not an afterthought.

Modular Solutions – Crypto

For cryptocurrency mining, modularity is equally essential — but with different constraints around density, energy, and thermal reuse. We design modular mining cooling platforms analogous to containerized or skid-mounted systems. Container or skid modules pre-integrated with racks, coolant loops, CDU / Smart Control System, power distribution, and dry cooling. Hydro cooling / direct liquid cooling (DLC) loops designed for ultra-low PUE, zero-water (dry cooler) operation, and high-density deployment.

Cooling Distribution Units (CDUs)

The Coolant Distribution Unit (CDU) is a core component in any liquid-cooled installation: it bridges between facility water loops and the secondary cooling circuits serving racks, cold plates, or modules.

In our systems, we design and integrate CDUs (also called Smart Control Systems, SCS) tuned to each deployment’s scale and redundancy needs. Features typically include: flow and pressure regulation, separation between primary (facility) and secondary loops, modular placement options, communication and monitoring: control logic, sensors, automation, and integration with facility BMS, scalable designs that allow parallel or staged expansion

Prefabricated Technology Cooling Loop Piping

Beyond major modules and CDUs, the plumbing and hydraulic infrastructure that connects everything is equally critical. We offer prefabricated cooling loops (pipe segments, manifolds, headers, connectors) built off-site and delivered with quality control, ready for field installation. Our approach emphasizes: stainless steel or corrosion-resistant materials (precision fabrication, pre-tested welds and joints), modular headers, branch manifolds, quick-disconnect fittings, and plug-and-play coupling systems, reduced on-site labor (faster commissioning, fewer errors in alignment or leak points), seamless integration with our TCS designs (ensuring hydraulic balance, minimal pressure drop, and reliable flow).

High-resolution 3D laser scanning

Using Trimble scanners, we capture existing environments with millimeter precision — ideal for complex mechanical spaces and brownfield upgrades.

BIM-ready 3D models

We deliver clean, structured models in Revit, Navisworks, or AutoCAD Plant 3D for coordination with architectural, mechanical, and MEP teams.

Retrofit planning & clash detection

We help clients reconfigure or expand existing sites with minimal risk, using real-world geometry to support piping layout, cooling integration, and equipment fit.

Digital twin integration

Our models can serve as the foundation for long- term asset tracking, condition monitoring, and upgrade simulation — built for real use, not just visuals.

3D Scanning & BIM

Point Cloud Scanning,

Modeling in Revit/Navisworks,

AEC Integrations

We support data center, crypto mining, and industrial clients with high-precision 3D scanning and digital modeling services tailored for retrofits, expansions, and new designs. Our team combines field accuracy with BIM-ready deliverables to ensure design alignment and construction efficiency.

WORKFLOW

Client Collaboration Process

We believe that successful cooling infrastructure doesn’t start with equipment — it starts with engineering insight, practical constraints, and client-specific goals. We work closely with our partners to deliver custom liquid cooling systems that are efficient, scalable, and field-proven. Whether it’s immersion, hydro, or direct-to-chip cooling, our role spans every stage of deployment — from concept to commissioning.

1. Discovery

Technical Consultation and Site Requirements

We begin by understanding the specific goals, constraints, and conditions of your project.

- Energy strategy and performance goals — defining efficiency metrics, load profiles, and power usage targets.

- Site layout and infrastructure assessment — reviewing available power, water, and climatic parameters to determine optimal cooling options.

- Hardware and system compatibility — aligning solutions with ASIC, GPU, and server requirements for stable, high-density operation.

- Environmental and scalability planning — ensuring the design can adapt to future load expansion and sustainability standards.

The goal is to define the most appropriate cooling approach from the outset.

2. Design & Simulation

System Design, Simulation & Engineering Blueprint

Once the project scope and requirements are defined, we move into the engineering phase — turning concept into a detailed, data-driven design. At this stage, our focus is on precision, efficiency, and long-term reliability.

- Hydraulic and thermal calculations — verifying flow distribution, heat rejection capacity, and operating stability under varying loads.

- Component selection and sizing — choosing the optimal pumps, heat exchangers, valves, and sensors to ensure both performance and redundancy.

- Material and fluid compatibility planning — defining the right media, corrosion protection, and fluid chemistry for operational durability.

- Automation and control logic integration — embedding real-time monitoring, predictive control, and BMS connectivity into the system design

The result:

A complete, ready-to-build engineering blueprint, validated through simulation and prepared for smooth implementation on-site.

3. Execution

On-site Supervision,

Commissioning,

Support

We oversee the implementation directly or in partnership with your contractors to translate design into reliable, real-world operation — ensuring seamless integration and verified system performance.

- On-site supervision — overseeing mechanical installation, piping connections, and equipment setup to meet all hydraulic and thermal design parameters.

- Commissioning and calibration — fine-tuning flow rates, temperature differentials, and automation logic for stable, efficient operation.

- Safety and compliance validation — verifying adherence to mechanical, electrical, and environmental standards before handover.

- Knowledge transfer and operator training — empowering your on-site team with the insights needed for confident, independent system management.

Our objective:

A fully operational, intelligent cooling system — optimized, monitored, and performing from the very first day.

4. Optimalization

Audits, Upgrades,

Post-launch Enhancements

Our involvement doesn’t end at commissioning — we continue to ensure your cooling infrastructure performs at its peak throughout its lifecycle.

Through continuous monitoring, optimization, and upgrade planning, we help you maintain maximum efficiency, adaptability, and reliability under real-world operating conditions.

- Performance diagnostics and predictive monitoring — analyzing operational data to maintain consistent efficiency and uptime.

- Dynamic system tuning — optimizing flow, temperature, and control logic for changing workloads or seasonal variations.

- Upgrade and expansion design — adapting the system to new capacity, technology, or infrastructure requirements.

- Maintenance and fluid lifecycle management — ensuring long-term stability through condition tracking and periodic analysis.

Our goal:

To keep your cooling ecosystem reliable, efficient, and future-ready — long after deployment.

Why nxc?

Proven Field Experience

We bring hands-on expertise from over 15 deployed liquid cooling systems worldwide — across mining, HPC, and data center sectors.

End-to-End Delivery

We handle the full lifecycle: from concept and design to on-site supervision and system commissioning. No outsourcing of critical steps.

Scalable, Modular Solutions

Our systems are built to grow — from containerized skids to rack-integrated DLC. Suitable for both pilot setups and full-scale rollouts.

Fast Project Turnaround

We’re able to move quickly — most projects go from design to launch in 2–20 weeks, depending on scope and site readiness.

Custom or OEM Integration

We design systems tailored to your hardware or integrate with your own infrastructure standards.

Flexible Engagement Models

Work with us on a consulting basis, as a design partner, or through bundled product-service offerings — whatever fits your strategy.

CONTACT

Start your project

Let's discuss your cooling infrastructure requirements and explore tailored solutions.